Related Links

How PurAll Works

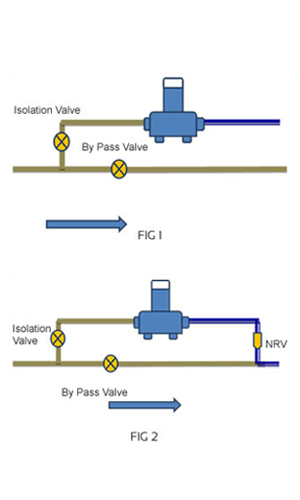

Schematic of installation of purall model for piped water supply schemes.It is recommended that PurAll device be connected to the main raw water supply line as per Fig 1above. Only in rare case, if installation as per Fig 1 above is not possible, then PurAll be installed as per Fig 2 above. The valves used should be of the type that will not restrict the flow very much, such as ball valves or gate valves. During operation it will be necessary to take samples downstream of PurAll to check the chlorine residual. The sample must be drawn after the chlorinated flow has merged with the bypassed flow. A sample tap might be installed for this purpose.

In operation, the water flows by gravity through the bypass line (Fig 1) or in a pressurized bypass line (Fig2) through PurAll. In this arrangement adequately chlorinated water is mixed in raw water to have desired free chlorine The dose should remain relatively constant regardless of the rate of flow.

The chlorine dose so adjusted should be sufficient to satisfy the chlorine demand and provide a residual level in the distribution system. If PurAll adds more chlorine to the water than is needed for these purposes, the chlorine dose can be controlled by the amount of water bypassing PurAll. To increase or decrease the dose the bypass valve may be adjusted to divert more or less water through PurAll. During operation the bypass valve will normally be partially or completely closed for flow control and the isolation valve will be partially or wide open. The valves once adjusted are seldom required to be changed for a site, unless there is a marked change in raw water parameters- viz flow rate.

Brief Information::

-

The rate of chemical consumption will vary according to flow rate and the chlorine demand of the Water

-

It is advised that the cartridge should not be exposed to air for long time. Cartridge should not be kept submerged / soaked in water for long time. The cartridge shall be needed to be replaced once the chemical inside is consumed; which shall be determined by the chlorine demand and water consumption

-

After usage of the cartridge for the desired literage of water, a new cartridge needs to be inserted

-

This is an easy operation and can be done by any unskilled operator

-

The material used for the cartridges is recyclable plastic or can be disposed in an eco-friendly way

-

First, it must be determined whether the candidate system is appropriate for the installation of a PurAll

-

A device for measurement of chlorine residual should be available in each community that is installing a PurAll Water Purifying device. The correct chlorine dosage is determined by measuring residual chlorine in the water. It is most effective to measure the chlorine residual at PurAll and at one or two points of use in the distribution system. A simple and inexpensive color comparator is a convenient method of measuring chlorine and is recommended for this purpose. Allowable residual chlorine content in water recommended by WHO is min 0.2 mg/liter

-

The candidate water system should have an enclosed water source and an enclosed delivery system. PurAll is designed for use in enclosed systems with a minimal amount of organic matter present. If an open source and / or open delivery system are used, the water may contain excessive amounts of impurities that may make treatment by simple chlorination ineffective

-

Open contaminated sources may require pretreatment

-

PurAll should be installed at a location accessible for maintenance and monitoring purposes

-

Reservoir:The tank at which PurAll is to be installed should have the following characteristics. The influent pipe (where PurAll will be installed) should enter the tank above the high water level. A hatch for maintenance is recommended. The tank should be in an accessible location